Making Electric Vehicles (EVs) Safer

More power and faster charging increase the risk of fire breaking out in electric vehicle (EV) battery compartments. New battery safety standards require a fresh look at how to effectively fireproof EV batteries.

With the continuing growth of the global electric vehicle (EV) market, battery technology advancements are leading to faster charging, higher energy, and longer cycle life. Related safety concerns about battery failures and fires also are growing.

If excess heat builds up in a battery because the cells are generating a lot of power, or are being charged rapidly, a fire can break out. A fire can also occur if a battery is damaged.

5 Minutes That Could Save Lives

With 3.31 million new energy passenger vehicles sold in 2021, China has a 53 percent share of the global EV market. In response to EV-related fires (at least one per week), China issued a new national safety standard: An EV must give passengers a five-minute advance warning of a hazardous situation due to thermal runaway and propagation from the vehicle battery.

Similar regulations are coming into force in Europe and North America.

Consequently, EV battery manufacturers worldwide need to take measure to ensure that drivers and passengers have five minutes to stop and evacuate their car should a fire break out in an EV battery,

One such measure involves limiting thermal runaway and thermal propagation by coating the battery cover with intumescent materials. These swell under the influence of high temperature to form a charred multicellular layer, which then acts as an insulating barrier and slows heat transfer.

Learning From the Oil and Gas Industry

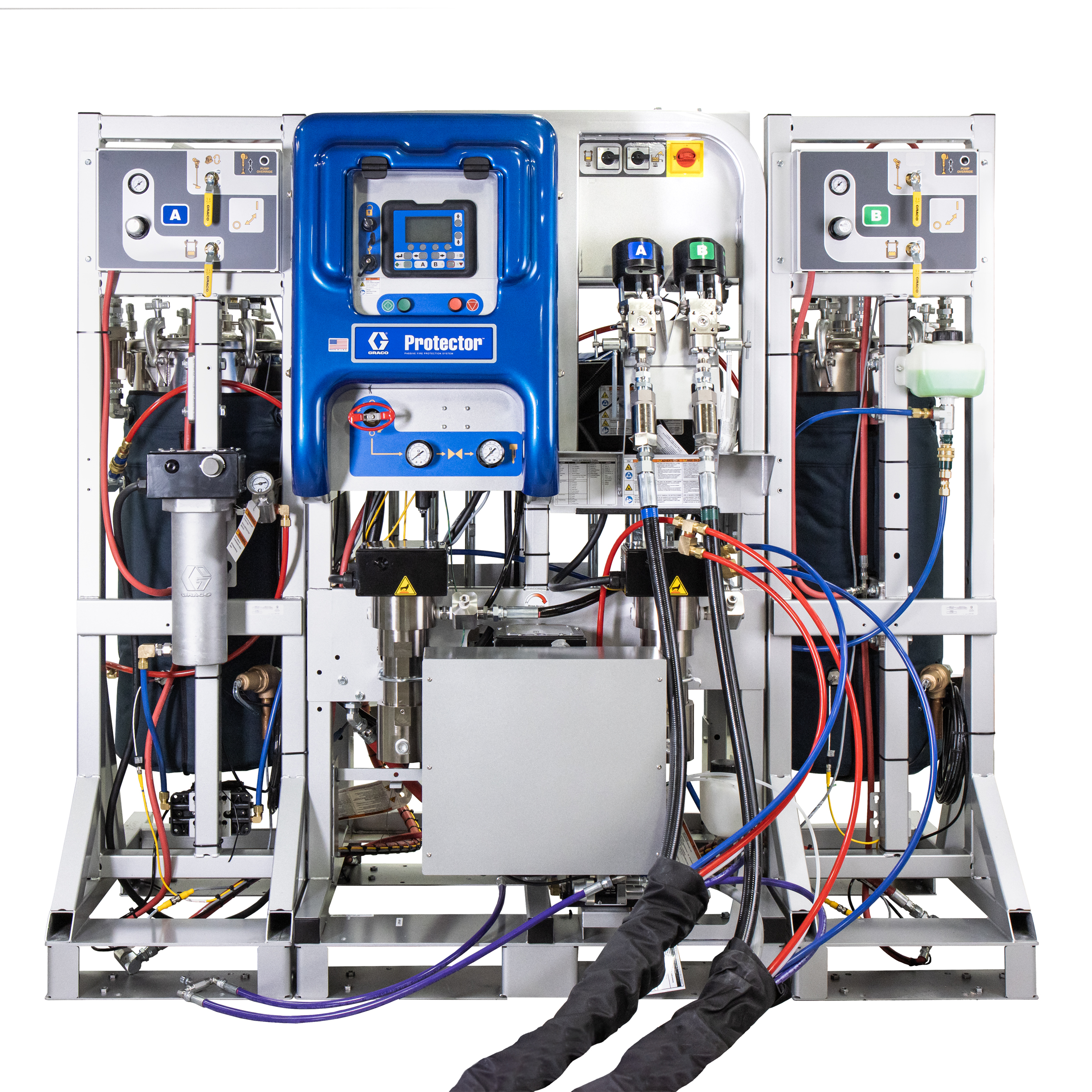

Intumescent materials have been used for decades in the oil and gas industry. Graco offers a full line of passive fire protection (PFP) sprayers designed to apply a broad range of intumescent fireproofing materials on pipe racking, I-beams, structural steel, storage tanks and more in the oil and gas industry.

Specifically, XM PFP technology is used worldwide to mix and spray intumescent coatings. XM PFP components specially selected for this application include:

- High pressure pumps force the viscous materials through lines. In addition to being composed of 100 percent solids, intumescent materials containing fibers to reinforce the coating can require up to 6,000 psi pumping pressure to convey the material.

- Heaters bring component material to proper temperature before pumping. At ambient temperatures, intumescent epoxy materials are too thick to pour from the container. To condition the material and properly feed the metering pump, the material must be both heated and agitated under pressure.

- Heated manifold helps provide consistent coating temperatures in cold climates.

- Spray tips tailored to high-viscosity materials are essential. Where spraying standard protective coatings typically employs orifices of less than 0.025 inches, intumescent epoxy coatings typically require orifices in the 0.035 to 0.039 inch range.

- Large hoses and valves are typically used in plural component PFP equipment. Hoses are often 3/4 inch in diameter. Dosing valves and ball valves are sized to allow a proper flow of both components. The static mixer has a 3/4-inch interior diameter and the spray gun also has larger fluid porting than a standard airless gun.

“Because of our considerable experience in spraying epoxy intumescent materials in the oil and gas industry, we were approached by a Tier 1 EV battery manufacturer to offer a solution to fireproof their EV battery covers,” explains Stephan Rindfleisch of Graco's eMobility Customer and Innovation Center in Germany. “Although the general operating principles would be pretty much the same, we soon realized we would have to significantly adapt our current products for this new application.”

Specific Requirements for EV Battery Covers

The main challenge facing Rindfleisch and the Graco eMobility team was the difference in safety window. On an oil rig, for example, intumescent material needs to provide a safety window of 60, 90 or 120 minutes to enable evacuation. This requires intumescent material to be sprayed to a thickness of between 4 and 12 mm.

For the five-minute safety window of an EV battery, a layer of intumescent material of only 0.6 to 1.2 mm is required.

One might imagine that spraying a thin layer is easier than spraying a thick layer. "Not at all," explains Rindfleisch.

"Epoxy intumescent material is a thick, high viscosity, fiber-filled material. Getting a repeatably consistent thin layer is extremely challenging! It’s easier to spray a thick layer.”

This challenge was met by customizing Graco’s existing XM PFP technology for a new purpose.

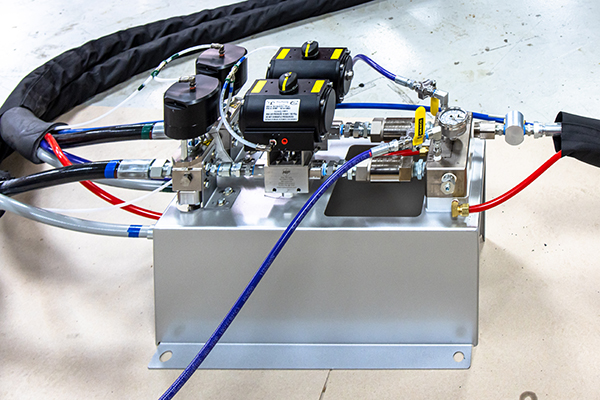

- The manual ball valves were removed and replaced with automatic ball valves.

- The shutter valves were redesigned.

- New automatic feeding lines were installed to automatically refill the tanks.

- Recirculation lines were added.

Communication protocols were added to make sure that the system could communicate with the industrial ethernet standard PROFINET, the communication backbone for Industry 4.0 factory automation.

The customized system for spraying fire protection coating on EV batteries included these main components:

- Central bulk supply system from 200-liter drums, with a tandem, double-post ram supply per component

- Conditioning tank for each component, including a double-walled, heated pressure tank, back-geared agitator, guided radar level sensor and an automatic refill portion, mounted on a stand

- Proportioning unit with variable mix ratio (1:1 to 10:1), including high-pressure dosing pumps, two high-volume fluid heaters, dosing valves and electronic controls as well as communication gateways to be integrated in a production environment

- Bundle of heated hoses to transfer the two components to the mix manifold, including return hoses for fast heat-up times, a solvent supply line and all necessary water and air lines to maintain temperature and control valves

- Automated mix manifold with automatic shut-off valves, automatic recirculation valves and solvent connections

- Additional heated hose bundle for transfer from the mix manifold to the automatic spray gun with a temperature and pressure sensor option at the gun manifold

- Automatic airless spray gun, mounted on the heated manifold

- Central solvent supply system with a high-pressure, high-volume piston pump

Customized Prototype

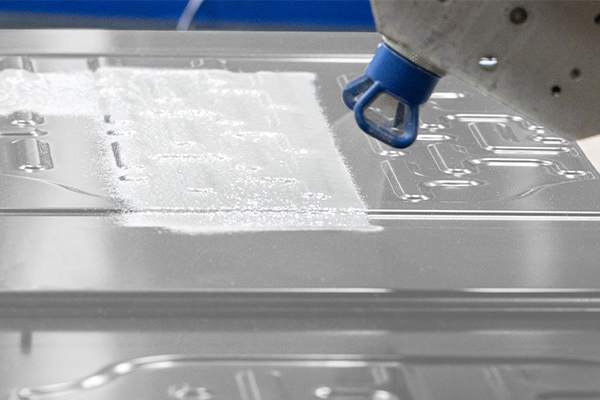

The prototype was tested with an integrator in Germany and passed with flying colors. It enabled a thin and uniform layer of epoxy intumescent material to be automatically sprayed on one side of an EV battery cover in just 25 seconds.

Prior to spraying, a robot adds masking to cover up mounting holes. Immediately after spraying another robot removes the masking.

“Depending on the size of the EV battery cover, one or two robots are used to spray simultaneously,” adds Rindfleisch. “The battery cover can then be flipped and the external side sprayed if necessary. This would protect the battery from being damaged by a fire external to the battery.”

A Chinese robot manufacturer ordered the customized solution for use on the production line of a European automotive manufacturer. A similar customization for North American system integrator soon followed.

With EV demand increasing and new battery safety regulations coming into force, manufacturers and integrators need partners like Graco, who can provide efficient intumescent material spraying solutions.

This article originally appeared in the 2022 autumn issue of e-mobility. Read the original article on e-motec.net.

CONTACT EV BATTERY EXPERTS

We understand the complexity of electric vehicle (EV) battery designs, and how material application affects their manufacturability and ability to mitigate thermal runaway events. We look forward to collaborating with you.

EV Battery

Explore sealing, bonding, and thermal management solutions for electric vehicle (EV) and hybrid vehicle (HV) battery pack and module assembly.

Related Articles

Fireproofing for EV Battery

Fireproofing plays a crucial role in the safety of electric vehicle (EV) batteries. Passive fire protection (PFP) coating performance depends on proper spray equipment.

Extreme Material Abrasiveness? Problem Solved with Elite

Some thermal interface materials (TIMs) are so abrasive, it’s like pumping diamond dust or liquid sandpaper. Explore why and how we developed Elite, the longest-lasting pump construction for abrasive material dispense.

Foam Encapsulation of Cylindrical Cells

Careful attention to thermal management and foam encapsulation are important to manufacturing high-performance battery modules that remain safe in any circumstance.